LEAK TEST 2.0

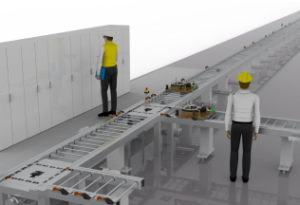

LEAK TEST 2.0 is a device designed for accurate evaluation of tightness and volume for a wide range of products and applications. It can measure the leakage of air or other media in closed products that have been welded, glued, pressed or folded into a closed unit in the previous process. The measured volume with the help of the LEAK TEST 2.0 device is very accurate and quickly evaluated on the basis of comparing the conversion of measured values. There is a measuring adapter with LED indication of the process status and an evaluation system with a database. The buttons on the adapters and the touch panel with multi-language visualization are used for control.

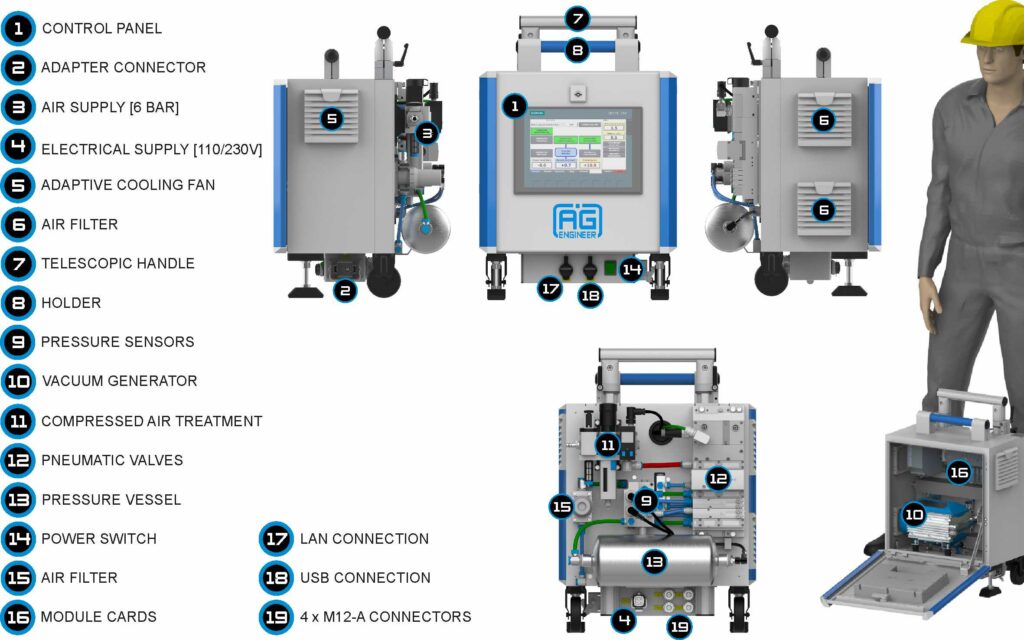

LEAK TEST 2.0 can be used as a manual device operated by workers in normal operation, as well as part of production, where it can be connected to a robotic system in automated mode.

This device is categorized with its accuracy and compactness among professional diagnostic-calibration devices used in various applications and production processes.

PRINCIPLE OF MEASUREMENT

1. Measurement by pressure (vacuum)

This measurement is based on the calculation of the pressure difference – the difference between the measuring pressure at the beginning and at the end of the measurement [mbar / min]. The measurement uses an accurate pressure transducer called –SD1 and –SD2.

The result of the measurement is the pressure difference dP = P1 – P2.

The result is given in units [mbar / min].

• P1 – is the vacuum in the product, after stabilization of the measuring pressure, at the beginning of the measurement.

• P2 – is the vacuum in the product, after stabilization of the measuring pressure, at the end of the measurement

2. Measurement using a flow rate

Device is design with an air flow sensor – AFM with a range of -400 … 400 sccm. The result of the measurement is the air flow AF after stabilization of the measuring pressure. The result is given in units [sccm] (standard cm3 per minute). The measured leakage by both measuring principles is given in measurable units, depending on the sensors used. To convert the leakage value in units [cm3 / min], the leakage conversion characteristic is used, for each method separately. This gear characteristic is obtained by calibrating the device, in which the so-called Leakadapter.

Leakadapter is a device (valve) that has a known leakage in units [cm3 / min]. This is a leak caliber. The lectest determines the dependence of the leakage on the measured dP or AF.

Another function is to measure the volume of products based on comparison and recalculation of measured values. This function is used for complex product shapes, where it is necessary to measure its exact internal volume for other applications in production.

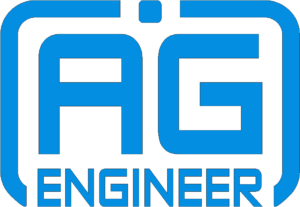

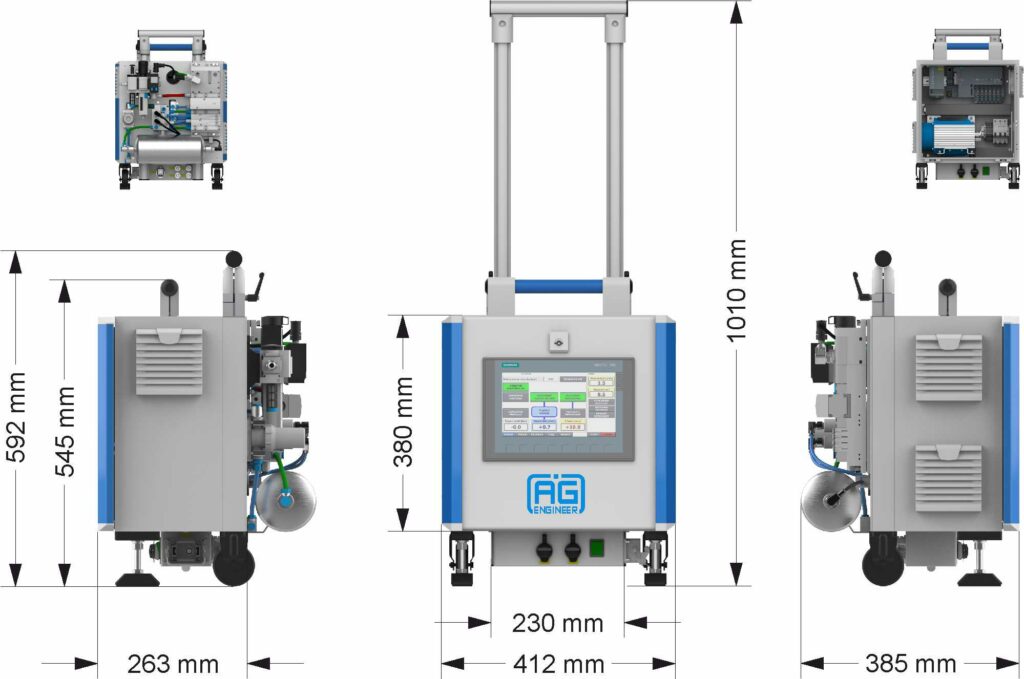

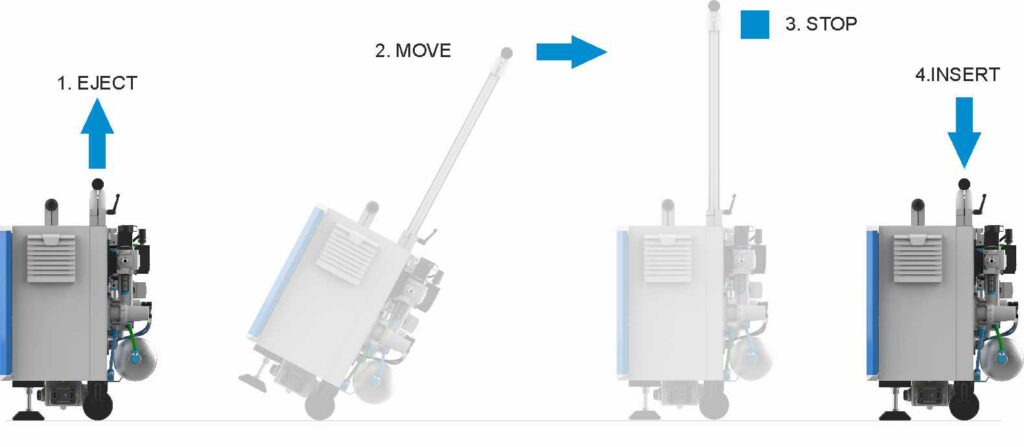

COMPACT DIMENSIONS AND HANDLING

Construction on wheels with a telescopic handle for easy handling. The electrical elements are located in a lockable cabinet and there is an open part with pneumatic components on the back. There are no handles or castors in the static version.

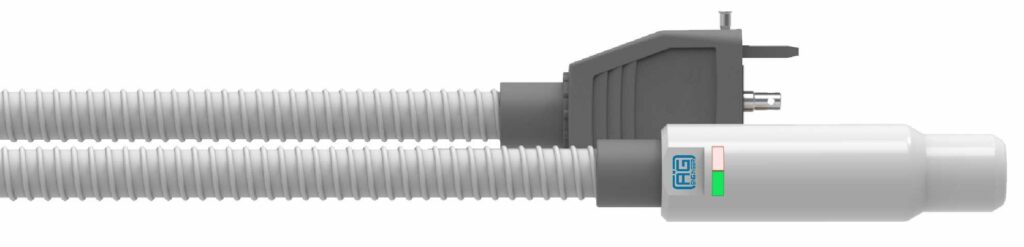

CONFIGURABLE ADAPTER FOR VARIOUS APPLICATIONS

Measuring adapters are design exactly to measure according to the client’s requirements with a light indication of the measuring status. Measuring adapters are manufactured with clamping systems in the form of a latch or sealing element on the adapter outlet. The adapter connector has multiple input pins to which the sensing technique of product presence or adapter clamping condition can be configured for increased safety and reliability of the measurement process.

WARRANTY AND POST-WARRANTY SERVICE

– we offer a 1-year warranty service for our equipment

– post-warranty service and delivery of spare parts

– device calibration

POSSIBILITY OF ADDITIONAL FUNCTIONS

– customized adapter for the specific measurement application

– modification of the application according to the client’s requirements

– possibility of delivery of spare parts

– installation at the workplace

About us

Our company operates in the field of industrial automation. It deals with design, development, design, wiring and filtered engineering, according to customer requirements.

When solving projects, we work with the latest technologies, we provide comprehensive services from design to delivery of equipment to customers. Of course, our work is the delivery of the necessary documentation and training for the operation and maintenance of the supplied equipment.

The company further specializes in the implementation of specific applications, such as integration work and optimization of device functionality. AG Engineer is a guarantee of a complete systematic solution for your production.