1. Consultations

Before starting the implementation of the project, we start with consultations with the customer for the best possible acquaintance with the technical task.

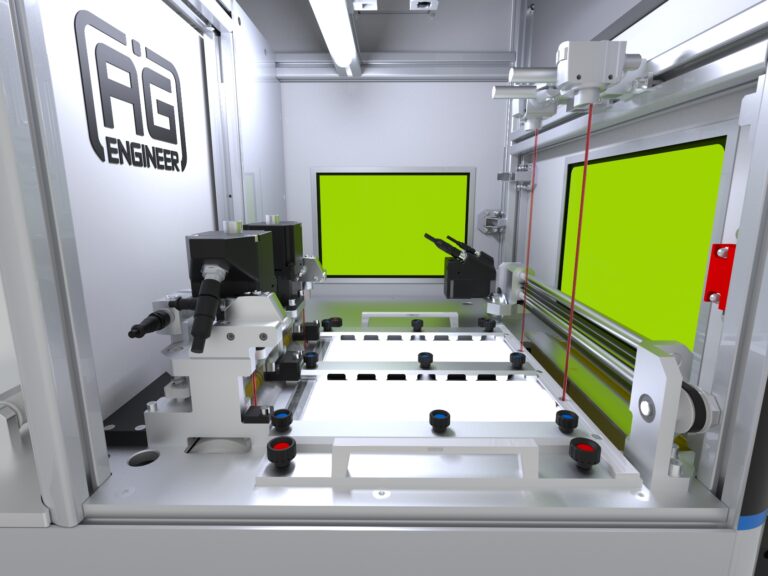

2. Design of our solution

Our design consists of visualization of the equipment / workplace, drawings, the principle of operation of the entire system, a schedule and a price offer.

3. Project design

Our team with divided tasks and a deadline takes the steps to prepare the project for the final form.

4. Presentation

The final presentations for the customer are a combination of previously agreed steps and our creation of output data from design activities.

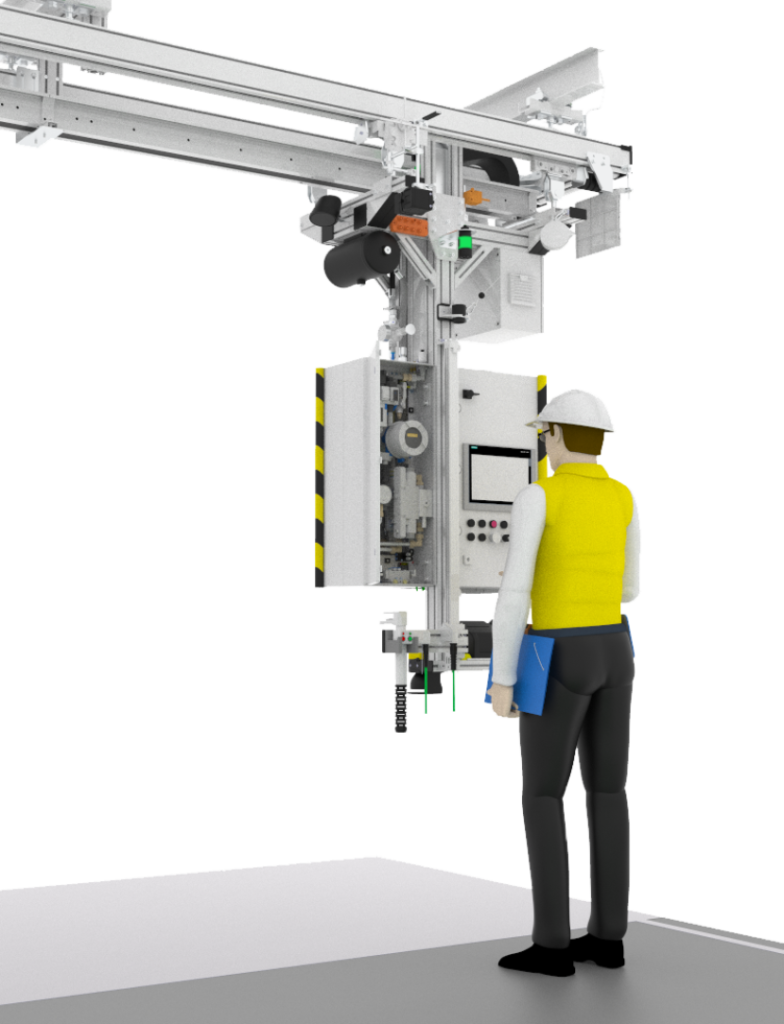

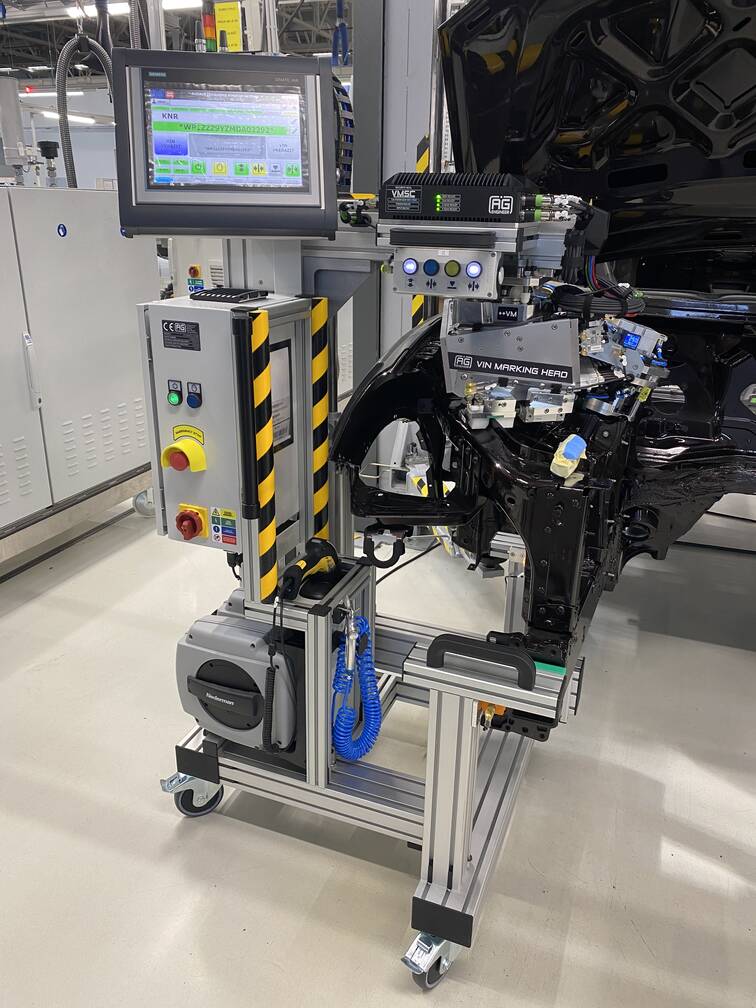

5. Installation

Our installations take place during racing holidays, but also during production where we are used to adhering to strict conditions, without restricting the operation of the lines.

6. Testing and optimization

For diagnostics and testing, we use methods with which we can detect an ineffective (unreliable) group of members in time, which we then reduce - reorganize.

7. Project documentation

Our technology includes project documentation, which is submitted in printed form and also on CD.

8. Staff training

The training consists of an inspection of the systems used and going through all the points of the documentation. After trainings after which your employees will be able to completely operate the supplied equipment.

Reliability

The technical preparation is divided into several parts, in which the parts of the production equipment are prepared. The individual departments cooperate on a joint assignment, which was agreed by mutual agreement in the previous steps. The internal systems of the workplaces designed by us are characterized by reliability and clear markings identical to the submitted documentation. Identification of members is a necessity for possible additional optimization activities.

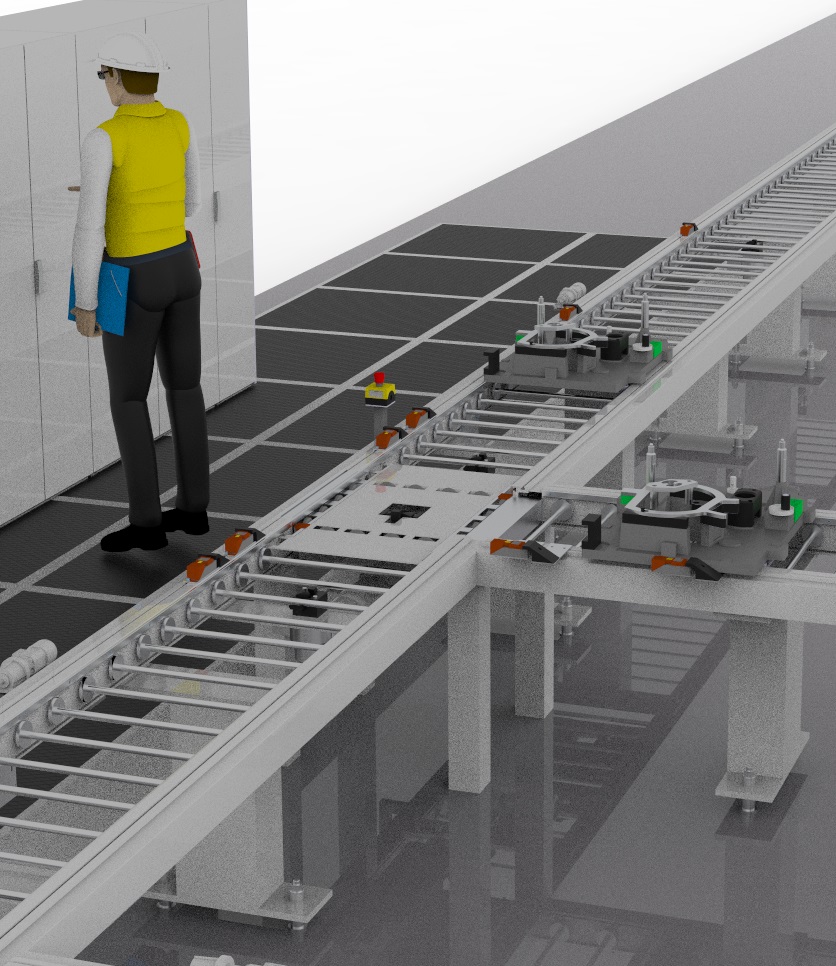

Precision

All machines and engineering networks are connected in such a way that all safety conditions of the given plant are met. The installations are carried out under the supervision of experts who have many years of experience in the field of design and installation and automated workplaces. When introducing devices into functional production, we apply optimization activities for the efficient operation of the line.

350

finished projects

19

Years of experience

Our company operates in the field of industrial automation. It deals with design, development, structural design, electrical installations and software engineering, according to customer requirements.